The Right System For The Application Can Maximize Operational Efficiencies In Aggregate Processing.

By Adam Brouwer

Selecting the best pumping system for an aggregate processing site means evaluating not only short-term needs – but also long-term productivity. Site owners and operators need to consider many parameters to determine what type of pumping system will deliver the best performance for the application.

They also need to compare the types of systems available and the benefits these systems offer under different conditions and application requirements. Consider these variables when evaluating the best pumping solution for a site:

Evaluate the Needs of the Site

Aggregate sites are harsh environments that can be difficult to access and challenging to maintain. High environmental pressures, safety demands and overall productivity all factor in to finding the right pump for a site’s needs. When evaluating a pump, consider:

- Topography: Where is the water or liquid you’re moving and where does it need to go? What’s the condition of the well?

- Site size: How much space is available to accommodate the pumping system?

- Mobility: Is the pump stationary, or will it need to be moved?

- Power options: Is electricity available? Can diesel fuel easily be transported to the site if needed?

- The environment: From sandstorms to blizzards, what type of precipitation, extreme temperatures and unexpected conditions might the site face?

Consider the Pumping System

Not all pumping systems are created equal – or created to deliver the same benefits. It’s important to evaluate the type of pump that will fit your site best, as well as the type of power that drives it. Consider these variables:

Surface Pumps vs. Submersible Turbines vs. Vertical Lineshaft Turbines – Surface pumps are designed to be used at ground level. Their rugged design and easy access make them ideal for wastewater disposal, reuse, slurries and tailings, as well as general dewatering. Self-priming versions will continue to reprime automatically after initial priming for less maintenance. The best surface pumps for aggregate applications will feature impellers designed with materials such as stainless alloys and high-chrome white iron that maximize resistance against abrasives.

Submersible and vertical lineshaft turbines are available in custom configurations to meet a variety of application requirements. Submersible turbines are typically paired with fully encapsulated or rewindable submersible motors for most general dewatering needs. They can also be used to access nearby water sources.

Submersible pumps are often ideal for smaller sites where there is limited real estate to house a surface pump, since these compact pumps are out-of-the-way and protected within the mine shaft. Submersible turbines are also better for portable applications since they are easy to move and relocate. Finally, submersibles are better designed for crooked wells compared to vertical lineshaft turbines.

Vertical lineshaft turbines can overcome many demanding site needs and challenging applications, like an open pit. For instance, an extremely short set vertical turbine can be mounted on a floating barge in low lying areas to help with dewatering during rainy seasons.

This type of setup is convenient since it does not require movement if the water level rises too quickly. Vertical lineshaft tubrines are typically chosen because of the wide range of pump speeds, materials of construction and oil lubed options that work great for higher amounts of solids. Some customers also feel more comfortable with the motor mounted above ground for ease of access and serviceability.

Diesel- vs. Electric-Driven Pump Packages – If electricity is available at the site, consider the benefits of an electric-driven pump package. If the mining application requires varying duty points, an electric-driven package with a variable frequency drive (VFD) can offer flexibility. This will allow the pump to meet the specific performance and efficiency requirements of each application.

Electrical packages also offer environmental benefits since they eliminate the need for diesel fuel and diesel exhaust fluid – minimizing harmful emissions and mitigating hazardous waste cleanup from leaks and spills. Recent advances in electric packages also allow for enhanced portability. New package designs that are built using a rigid motor stool mean no realignment is needed if the packages are moved.

While today’s electric-driven packages have cost and environmental advantages over diesel-driven ones, the site will need to have reliable access to power. If not, a diesel-driven pump package may be the better choice.

A diesel package ensures operation even when access to onsite power is limited. For vertical turbine installations, a diesel engine can be paired with a right-angle drive to ensure operation even in remote locations. Surface pumps are commonly paired with diesel engines on trailers to ensure ease of transportation and the ability to adjust site setup to maintain suction lift capabilities

Optimizing Your System With Variable Frequency Drives

Portable electric driven pump packages as well as stationary submersible and vertical turbines are typically paired with VFDs so that multiple performance conditions can be achieved with one pump simply by adjusting the speed. VFDs offer incredible benefits beyond this, including:

- Improved system life. Whether the VFD is operating a surface or submersible pump it can reduce the current inrush of across-the-line starts and keep the maximum current within the motor manufacturer’s recommended range. The soft start capability controls the electrical current and voltage as it is provided to the motor and reduces the system stress associated with each start-up. It also helps reduce the heat buildup in the motor: a key to prolonging motor life. Keeping starts per day within the motor manufacturer’s recommended range will help with system life — another setting that can be controlled with the VFD.

- Water table stabilization. In addition to optimizing the system, VFDs equipped with a water depth sensor can help stabilize water table levels across a mine in the event one pump in a system goes down for maintenance or inclement weather.

- Customizable to site needs. In selecting a VFD, consider the overall configuration and environmental requirements. Is it a standalone VFD or panel unit? What protection will it need from the weather? How important is ease of programming? Some manufacturers have engineered their systems so that drives can easily be paired with a variety of motors in minutes. For surface pumping systems, select manufacturers also provide the option of a standalone skid or an integrated design that’s mounted within the surface pumping package. This allows site managers to benefit from a VFD on their portable pumps.

Finalize the Selection

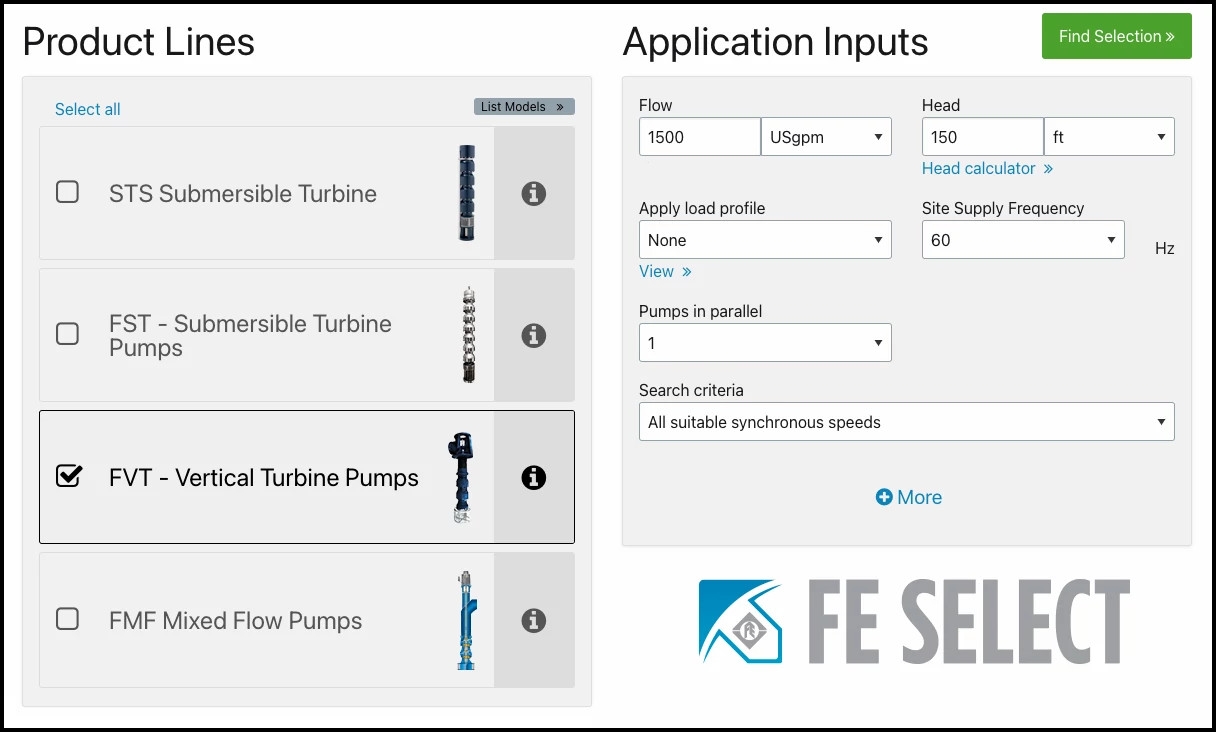

With all these options, how should an aggregate site manager select the best system for their application? Online tools can provide guidance, streamline selection and simplify ordering.

Here’s one example of how an online tool assists with selection, using the performance requirements of a general dewatering application. The tool prompts users to enter parameters, and then it does the rest: fully specifying what products are recommended, including the necessary components, a list price quote for the system, and links to related informational product documentation.

Since both surface and submersible pumps would be viable product choices for this application, the tool allows users to search for both types of products, starting with submersible and VLST application needs.

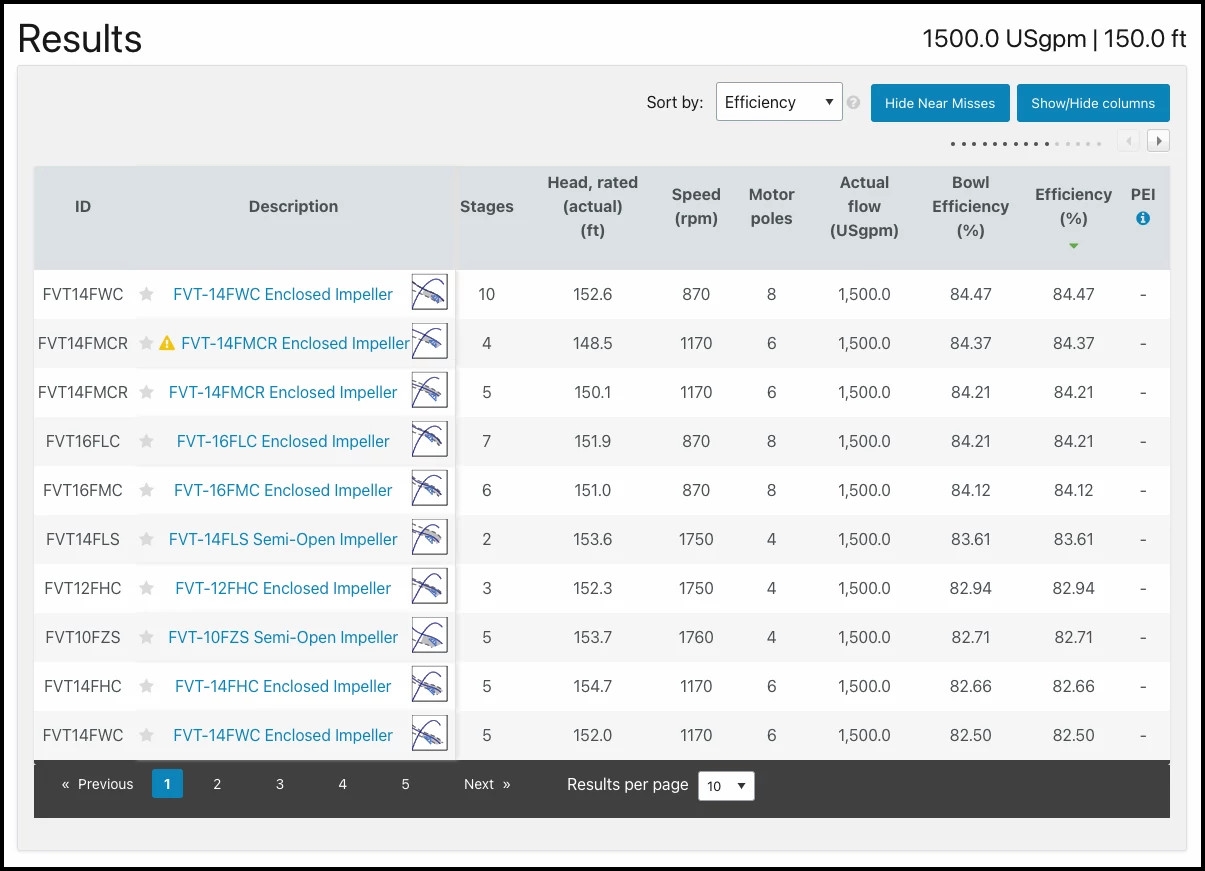

These inputs generate several results, sorted by hydraulic efficiency. The list can easily be narrowed down based on the parameters that are most important to the user: desired speed of operation, number of stages, bowl diameter, power rating and more. Most users typically look for a product that falls between 80% and 85% efficiency:

The tool then correctly matches the components necessary for the desired application, provides a list price quote for the package, and offers links to related informational product documentation as well as pump and motor performance curves.

The tool walks through the process from start to finish. Users can do either a basic search that requires only primary application data, such as flow and total dynamic head demands; or a more advanced selection that considers some additional variables unique to the situation. Does the application need a product that is temporary or permanent? How far is the closest water source and where does the pump need to be placed?

For example, a VLST is going to be easier to install in a 340-ft.-long mine that’s underground whereas a mine that’s 50-ft. long with above ground access will utilize a surface pump more effectively.

Conclusion

While selecting the best pumping system for an aggregate application requires users to consider a lot of variables, there are tools to help you get the best solution for your needs. With 24/7 online and mobile-friendly interfaces, online tools can walk users through the process from start to finish, instantly formalizing deliverables with printable and downloadable quotes – giving owners and operators what they need to keep operations running smoothly.

Adam Brouwer is global product manager – large pump electronics for Franklin Electric.